Dissipation in SiC nanoresonators is drastically minimized through back-side etching.

High-quality micro- and nanomechanical resonators are widely used in sensing, communications, and timing, and have future applications in quantum technologies and fundamental studies of quantum physics. Crystalline thin films are particularly attractive for such resonators due to their prospects for high quality, high intrinsic stress, high yield strength, and low dissipation. However, when such films are grown on a silicon substrate, interfacial defects arising from lattice mismatch with the substrate have been postulated to introduce additional dissipation.

Here, we develop a back-side etching process for single-crystal silicon carbide microresonators that allows us to quantitatively verify this prediction. By engineering the geometry of the resonators and removing the defective interfacial layer, we achieve quality factors exceeding a million in silicon carbide trampoline resonators at room temperature, a factor of five higher than those achieved without removal of the interfacial defect layer. We predict that similar devices fabricated from ultrahigh-purity silicon carbide, leveraging its high yield strength, could enable room-temperature quality factors as high as 6×109.

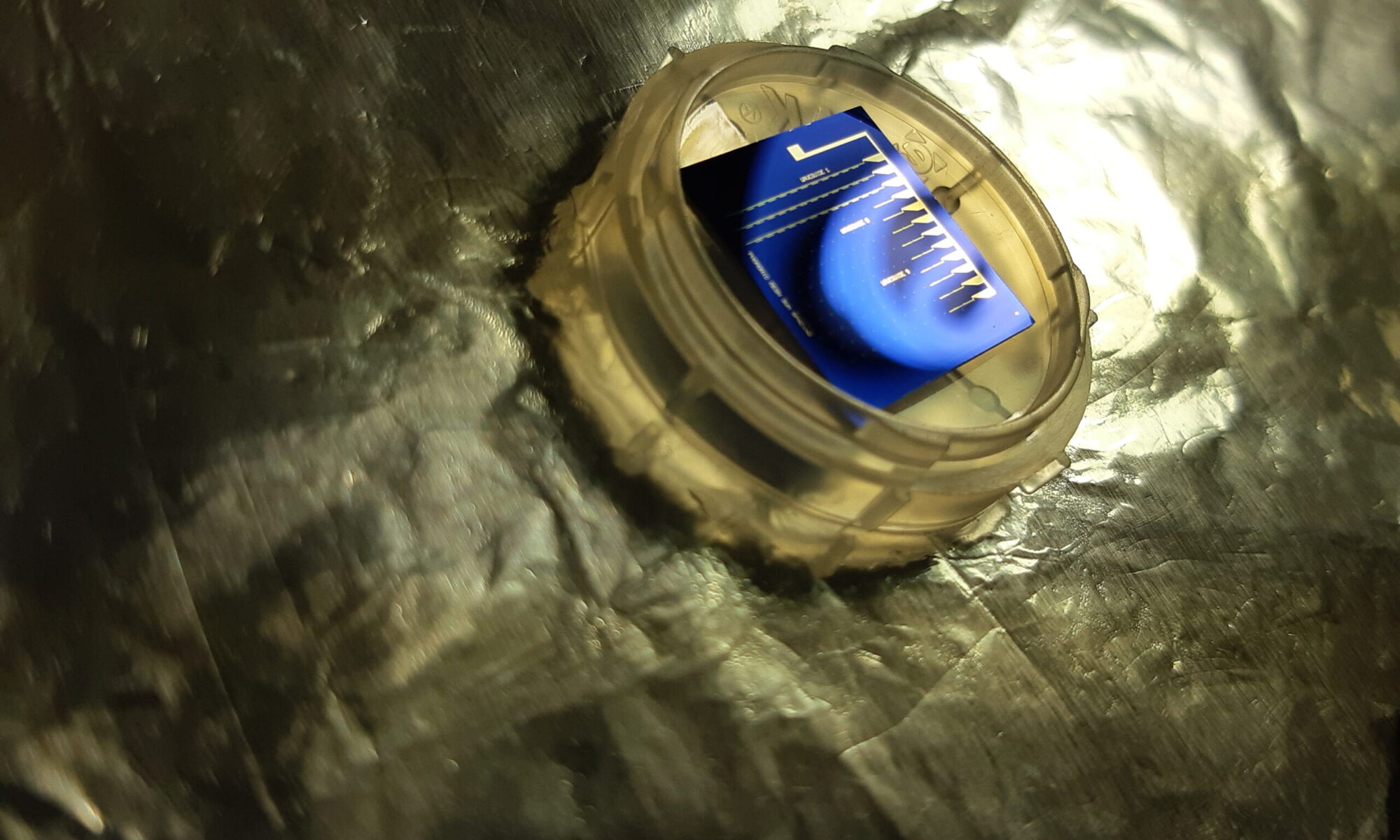

holder. The different colors of the four different chip sections

are produced by different thicknesses of the SiC. Each device is

released on a fully etched silicon window, which can be directly

observed in the image.

Bottom: SEM image of a SiC trampoline

resonator. The trampoline is suspended above a fully back-sideetched

hole in a 0.5-mm-thick silicon substrate.

From: Engineering the Dissipation of Crystalline Micromechanical Resonators

[1] First demonstration Q factors over a million using stressed SiC crystalline resonators, Appl. Phys. Lett. 104, 081901 (2014) http://dx.doi.org/10.1063/1.4866268

[2] Sensitivity limit of SiC string resonators, J. Appl. Phys. 119, 055304 (2016) http://dx.doi.org/10.1063/1.4941274

[3] First demonstration that crystalline defects affect the Q factors of crystalline resonators, Phys. Rev. Appl. 13, 044007 (2020) http://dx.doi.org/10.1103/PhysRevApplied.13.044007

Miscellaneous links:

Phononics: Engineering and control of acoustic fields on a chip, PhD thesis Erick Romero (2019)